In the maritime industry, the efficiency and reliability of fuel systems are paramount for the performance of marine engines. The intricacies of these systems must be understood to ensure optimal functionality and safety at sea. Properly engineered fuel systems encompass various parts that work in unison to deliver the right amount of fuel at the right pressure, guaranteeing that marine engines operate smoothly under various conditions.

Trust in US fuel systems derives not only from the advanced technology employed but also from rigorous testing and standards that fuel system manufacturers adhere to. These systems are designed to withstand the harsh environments of marine applications, where exposure to water, salt, and varied temperatures can significantly affect fuel performance. By focusing on the quality and reliability of each part within the fuel system, operators can mitigate risks associated with engine failure and ensure a safe voyage.

Moreover, understanding how these fuel systems function helps in maintaining them effectively. Different marine engines may require specific components tailored to their operational needs, making it essential for professionals in the industry to stay informed about the latest advancements and products available on the market. This knowledge fosters greater trust in the systems that power vessels, ultimately impacting the overall success of maritime operations.

Understanding Fuel System Components and Their Reliability

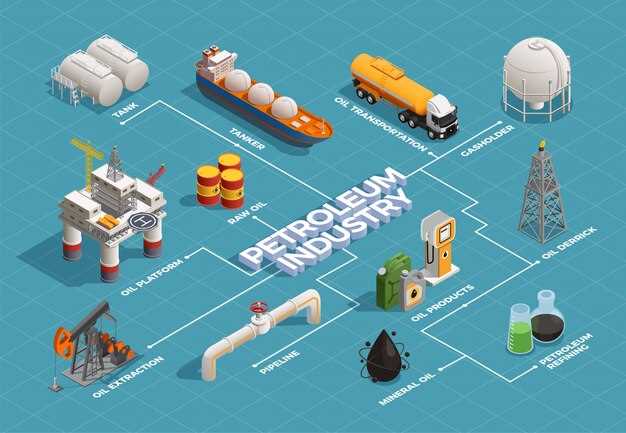

The reliability of marine engines largely depends on the performance of their fuel systems, which play a critical role in delivering the necessary fuel for optimal operation. A typical marine fuel system consists of several essential parts, each designed to ensure efficiency and safety.

At the core of the fuel system is the fuel tank, which stores the fuel until it is needed by the engine. The material of the tank is crucial, as it must withstand marine environments and prevent corrosion. Following the tank, the fuel lines transport the fuel to the engine. These lines must be durable and resistant to environmental factors to maintain an uninterrupted flow.

The fuel pump is another vital component, responsible for moving fuel from the tank to the engine. It requires regular maintenance to ensure reliability, as any failure can lead to engine stalling or inefficiency. Attached to the fuel pump is the fuel filter, which removes impurities and debris from the fuel, protecting the engine from damage.

In addition to these parts, injectors play a crucial role in atomizing fuel for optimal combustion. A reliable injector ensures proper fuel delivery, enhancing engine performance and reducing emissions. Regular inspection and cleaning of injectors are necessary to maintain their efficiency.

Lastly, the entire system relies on the regulator, which maintains consistent fuel pressure throughout the system. Fluctuations can jeopardize engine performance, so it is essential to monitor this component closely.

Understanding these fuel system components and their respective roles is fundamental for marine engine reliability. Regular maintenance and attention to each part can prevent costly repairs and ensure efficient operation on the water.

How to Choose Quality Marine Parts for Optimal Performance

Selecting high-quality marine parts is crucial for ensuring optimal performance of your marine engine. One of the first considerations is the source of the parts. Always purchase from reputable manufacturers known for their commitment to quality and longevity. Research brands that specialize in marine fuel systems, as they often provide parts that are specifically designed to withstand harsh marine environments.

Next, consider the materials used in the construction of the parts. Quality marine components are typically made from corrosion-resistant materials such as aluminum, stainless steel, and specialized plastics. These materials ensure that the parts can endure exposure to saltwater and other marine conditions without degrading.

Compatibility is another key factor. When selecting fuel parts, ensure they are designed for your specific engine model. Mismatched parts can lead to inefficiencies and potentially cause damage. Always check the manufacturer’s specifications and cross-reference part numbers to confirm compatibility.

Inspecting the design and engineering of the parts is also vital. Look for features that enhance performance, such as advanced fuel filtration systems or streamlined fuel delivery mechanisms. High-quality parts often incorporate innovative designs that improve efficiency and reliability.

Finally, consider customer reviews and feedback. Real-world experiences offer insights into the performance and durability of marine parts. Look for reviews that mention fuel system performance, installation experience, and longevity to gauge how well the parts may work for your needs.

In conclusion, choosing quality marine parts requires careful consideration of manufacturer reputation, material quality, compatibility, design efficiency, and customer feedback. Making informed decisions will lead to enhanced performance and reliability of your marine engine while ensuring a smoother and more enjoyable experience on the water.

Maintenance Tips for Ensuring Fuel System Longevity

Regular maintenance is crucial for the longevity of the fuel system in marine engines. Start by frequently checking fuel filters. Replace them according to the manufacturer’s recommendations to ensure optimal performance and prevent contaminants from damaging engine parts.

Additionally, routinely inspect fuel lines for any signs of wear or leaks. Damaged lines can lead to fuel loss and potential hazards, so it’s essential to replace worn components immediately. Make sure all connections are secure to prevent air leaks that can compromise the system.

Another key aspect of maintenance is keeping the fuel tank clean. Regularly cleaning and inspecting the tank prevents sediment accumulation, which can lead to clogging of system parts. It’s also advisable to use fuel stabilizers, particularly during off-seasons, to keep fuel fresh and minimize degradation.

Monitoring fuel quality is vital; use only high-quality marine fuel to reduce the risk of injector fouling and injector pump wear. Periodically testing the fuel can help ensure it meets required standards and is free of contaminants.

Lastly, schedule professional inspections of the entire fuel system. A qualified technician can identify potential issues before they become significant problems, ensuring that all parts perform at their best. Adhering to these maintenance tips will greatly enhance the longevity and reliability of your marine fuel system.