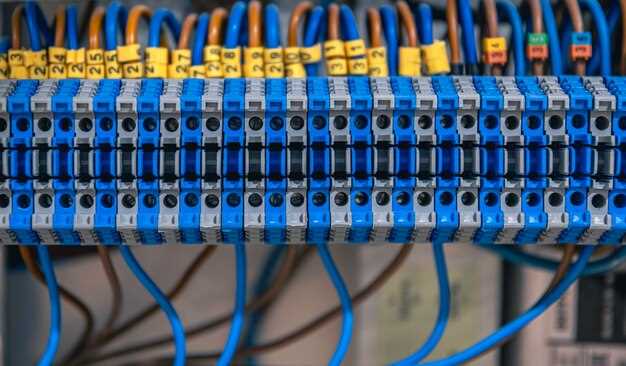

The importance of safety in electrical systems cannot be overstated, especially in industries where reliability is paramount. A verified wiring harness plays a critical role in ensuring that the complex web of electrical connections functions seamlessly. By utilizing verified components, manufacturers and engineers can significantly reduce the risk of short circuits, system failures, and potential hazards that may arise from faulty wiring.

One of the primary advantages of using verified wiring harnesses is the assurance of quality and performance. These harnesses undergo rigorous testing and certification processes, which means they meet established industry standards for durability and functionality. This reliability is essential not only for the longevity of the electrical system but also for the safety of the users and operators who depend on these systems every day.

Moreover, employing verified wiring harnesses simplifies the installation process and minimizes the likelihood of errors. When each harness is designed to specific guidelines and validated for compatibility, it enhances overall efficiency during assembly and repair. This not only saves time but also ensures that the harness operates as intended, thus upholding the highest safety standards in electrical applications.

Understanding the Impact of Quality on Safety Compliance

The quality of wiring harnesses plays a critical role in ensuring safety compliance across various industries. Compliant harnesses are designed to meet specific regulatory standards, which help mitigate risks associated with electrical failures and malfunctions. A high-quality harness ensures that electrical connections are robust, reducing the likelihood of shorts or other issues that could compromise safety.

When a wiring harness is manufactured with stringent quality control measures, it significantly enhances the overall reliability of the electrical system. Each component, including wires, connectors, and insulation, must adhere to established safety specifications. If any element fails to meet these standards, it could lead to catastrophic outcomes, affecting not only the equipment itself but also the safety of personnel and end-users.

In addition to mechanical integrity, the choice of materials used in wiring harness production is vital. Using verified materials that resist environmental factors–such as heat, moisture, and chemicals–can greatly enhance the longevity and safety of the harness. These factors ensure that the harness functions effectively under varying conditions, thus maintaining compliance with safety regulations throughout its operational life.

Another aspect to consider is the importance of thorough testing and certification of wiring harnesses. Proper testing processes validate that the harnesses perform as intended under real-world conditions. Compliance with industry standards, such as ISO or UL certifications, provides assurance that the harness meets safety requirements. This reduces liability risks for manufacturers and enhances trust among consumers.

Ultimately, investing in quality verified wiring harnesses not only fulfills legal obligations but also promotes a culture of safety within organizations. By prioritizing high-quality harnesses, companies can significantly lower the incidence of electrical failures, thereby ensuring the safety of their operations and personnel.

Identifying Cost Savings Through Reliable Wiring Solutions

Investing in verified wiring harnesses provides significant cost savings for businesses in the long term. Reliable wiring solutions enhance safety and durability, reducing the likelihood of failures that can lead to expensive downtime. Implementing high-quality harnesses ensures that systems function efficiently and minimizes the risk of electrical issues that could necessitate costly repairs.

High-quality wiring harnesses are designed to withstand harsh conditions, which prolongs their lifespan. As a result, companies can avoid frequent replacements and maintenance costs associated with inferior wiring systems. This longevity translates into fewer disruptions in production, allowing organizations to allocate resources more effectively and maintain productivity.

In addition to lower maintenance costs, dependable wiring solutions can also lead to improved energy efficiency. Reliable and safe harnesses optimize power distribution, which can reduce energy consumption. Lower energy bills further contribute to overall cost savings, enhancing a company’s bottom line.

Moreover, investing in verified wiring harnesses supports compliance with safety standards and regulations. Avoiding potential penalties for non-compliance not only saves money but also protects a company’s reputation. A commitment to safety fosters trust among clients and stakeholders, resulting in increased business opportunities.

Ultimately, identifying cost savings through reliable wiring solutions hinges on the choice of components. Verified wiring harnesses promise enhanced quality, longevity, and safety, making them a smart investment for any organization seeking to optimize operational efficiency and reduce long-term expenses.

Enhancing Performance with Certified Wiring Harness Technology

Certified wiring harness technology significantly contributes to the overall performance of electronic systems across various industries. High-quality wiring harnesses are engineered to meet stringent standards, ensuring reliability and efficiency in power distribution and signal transmission.

One of the primary benefits of using certified wiring harnesses is their ability to minimize electrical interference. With precise construction and the use of high-grade materials, these harnesses effectively shield sensitive components, leading to improved signal clarity and reduced noise levels. This is particularly critical in applications requiring high data integrity, such as automotive and aerospace sectors.

Additionally, certified wiring harnesses are designed for enhanced durability. They undergo rigorous testing to withstand harsh environmental conditions, including extreme temperatures, moisture, and vibration. The resilience of these harnesses ensures long-term reliability, reducing the likelihood of failure and the associated costs of maintenance and replacements.

The integration of advanced manufacturing techniques further elevates the performance of certified wiring harnesses. Automated processes reduce the risk of human error, resulting in consistent quality and precision in assembly. This attention to detail not only boosts performance but also enhances the overall safety of the electrical systems they support.

Moreover, certified wiring harnesses contribute to weight reduction in devices and vehicles. By utilizing lightweight materials without compromising strength, manufacturers can design more efficient products, improving fuel economy in automobiles and increasing the operational efficiency of various machinery.

In conclusion, employing certified wiring harness technology enhances overall performance by ensuring reliability, durability, and efficiency in electrical systems. As industries strive for innovation and efficiency, the role of high-quality wiring harnesses becomes increasingly vital in achieving these goals.